Disinfectant Wipe Solutions Tailored for Wet Wipe Factories

Although the pandemic has passed, awareness of disinfection continues to rise. Disinfectant wipes, one of the most common and practical disinfectant products, are widely used in households. Disinfectant wipes are not only convenient to carry but also offer antibacterial and disinfecting properties, preventing bacterial and viral infections to a certain extent. The liquid formula of disinfectant wipes determines their sterilization rate and safety.

Although the alcohol in disinfectant wipes has a good antibacterial effect, its irritation can be a major concern. Infants' delicate skin, in particular, is not suitable for direct contact with alcohol. Therefore, alcohol-free disinfectant wipes enriched with botanical ingredients are gaining increasing consumer acceptance. We specialize in providing alcohol-free professional technical services and solutions for wet wipe manufacturers.

I. Why choose an "alcohol-free + botanical ingredient" liquid formula?

75% alcohol has excellent antibacterial properties and can be used in alcohol wipes, but there are some significant drawbacks:

Alcohol has a strong odor and is highly irritating, which can easily cause skin dryness or allergies.

Alcohol is flammable, requiring extremely high safety requirements for storage and transportation.

Alcohol is highly volatile, which affects the seal and stability of wipes.

In contrast, alcohol-free plant-based formulas in wipes are not only effective but also gentle, making them suitable for the following applications:

Maternal and infant wipes

Household wipes

Public cleaning wipes (such as tables, chairs, and doorknobs)

Export to countries and regions with higher requirements for formula safety.

II. Alcohol-Free Disinfectant Liquid Wipes: Core Ingredient Composition

Based on extensive R&D experience and practical application needs, we have designed the following liquid formulas:

| Ingredient Category | Main Ingredient | Function |

| Antimicrobial Agents | Benzalkonium Chloride, Plant Extracts (such as Naringenin, Tea Polyphenols) | Broad-spectrum antibacterial, safe and gentle |

| Soothing Agents | Honeysuckle Extract, Aloe Vera Gel, Chamomile Extract | Relieve irritation and enhance skin friendliness |

| Humectants | Propylene Glycol, Glycerin | Prevent dryness and enhance lubricity |

| Surfactants | Non-ionic APG surfactants, cocamide | Provides cleansing power and controls foam levels |

| Conditioning ingredients | Sodium citrate, sodium EDTA, etc. | Stabilizes pH and enhances formulation compatibility |

| Preservative System | Phenoxyethanol + Ethylhexylglycerin | Extends shelf life without the use of formaldehyde-releasing agents |

Note: Ingredients can be flexibly adjusted based on market regulations in different countries (e.g., GB 15979, EU regulations, FDA, etc.).

III. Formula Design Principles: Safety, Stability, Efficiency, and High Compatibility

We adhere to the following standards when developing and recommending formulas:

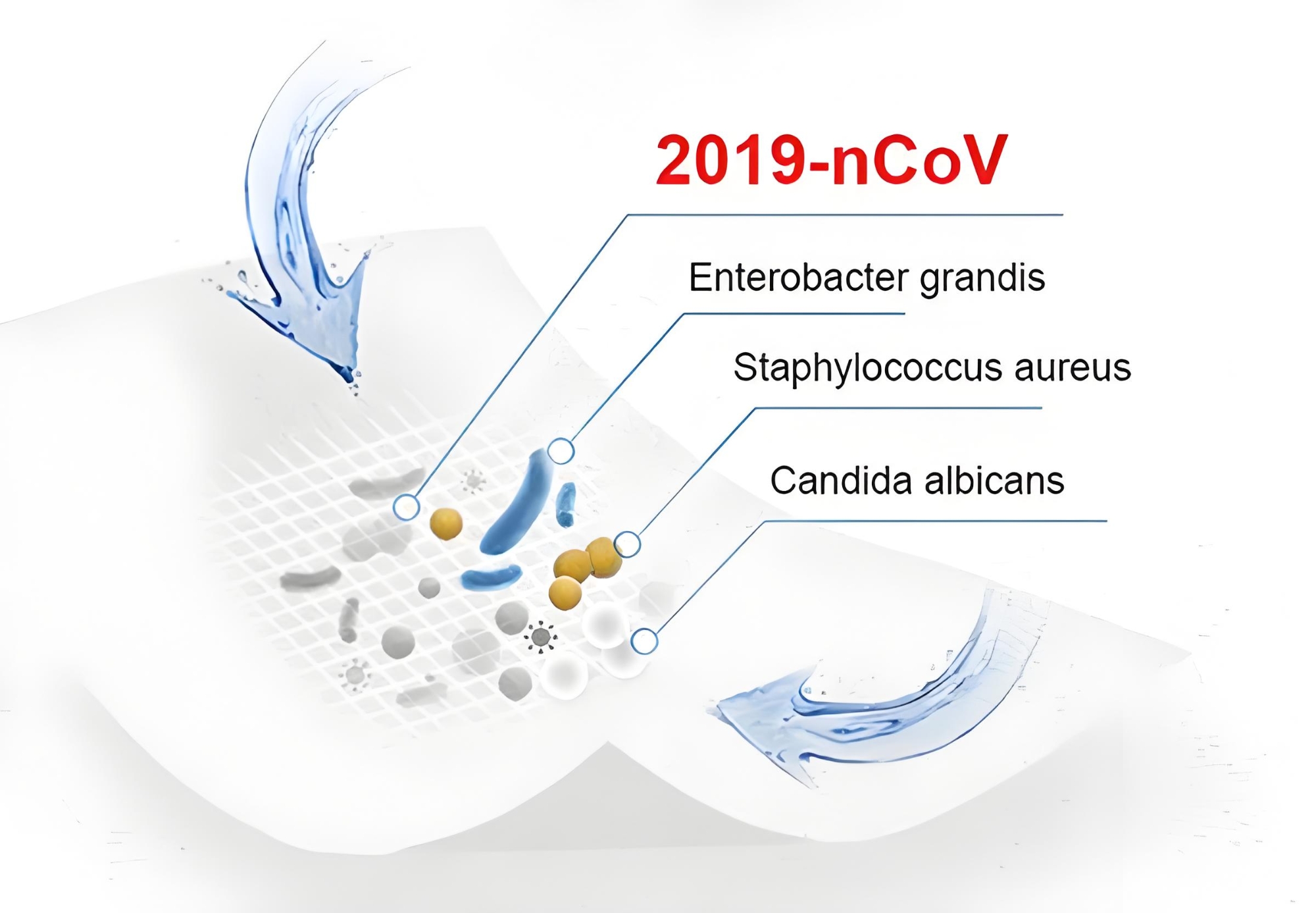

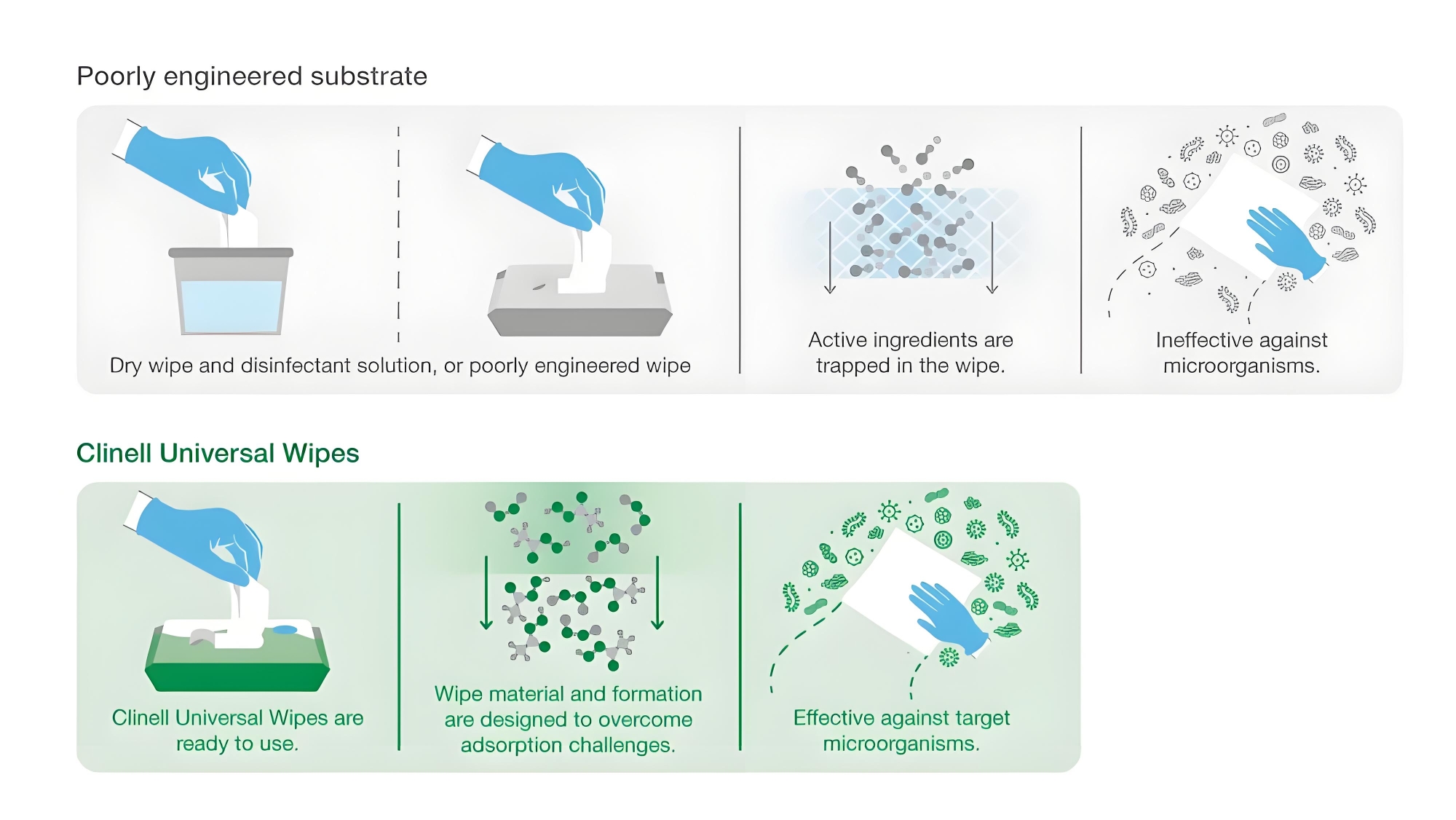

Antimicrobial Efficiency: Antimicrobial efficacy is a fundamental requirement of the preservative system. The formula must achieve an antibacterial rate of ≥99% against common bacteria such as Staphylococcus aureus and Escherichia coli.

Low Skin Irritation: Suitable for infants, children, and those with sensitive skin, it is gentle and non-irritating.

Stable Formula Structure: No separation or clouding occurs under high and low temperature conditions, ensuring safe long-term storage and transportation. Excellent compatibility: It does not chemically react with wet wipe packaging films and is compatible with a variety of fabric materials, including spunlace, biodegradable fabrics, wet towels, and bamboo fiber fabrics.

IV. Comprehensive, professional, and personalized technical services for wet wipe factories

As a professional service provider with over ten years of experience in developing wet wipe liquids and antibacterial disinfectant formulas, we not only offer existing proven formulas but also provide a complete suite of customized solutions tailored to the specific needs and local regulations of wet wipe factories:

✅ Customized Formulation Services

We provide comprehensive, professional, and customized formula design tailored to your factory's scale, existing equipment, product requirements, brand positioning, market regulations, and other requirements.

✅ Raw Material Matching Recommendations

We assist customers in selecting compliant, low-dosage, and cost-effective raw material systems to reduce formulation costs.

✅ Process Technical Support

We provide comprehensive process guidance from formulation to actual production, including detailed parameters such as dilution ratios and mixing sequences, as well as prevention of potential production issues.

✅ Third-Party Formula Testing

We accept third-party testing at any time, such as SGS and Guangwei Testing, to ensure that our products meet customer requirements, national standards, and regulatory standards.

✅ Pipe Cleaning Recommendations

For the pipe cleaning process of filling equipment, we provide water usage recommendations and cleaning agent recommendations to avoid cross-contamination.

V. Comprehensive solutions for liquid disinfectant wipes to meet the diverse product needs of wet wipe factories

The use of disinfectant wipes has become a growing trend, becoming ubiquitous in hospitals and everyday disinfection. Choosing the right liquid wipe formula can enhance product competitiveness and help you stand out from the competition.

English

English

USA

USA

西班牙语

西班牙语

俄罗斯

俄罗斯

葡萄牙

葡萄牙

印尼

印尼

巴基斯坦

巴基斯坦

尼日利亚

尼日利亚

孟加拉

孟加拉

墨西哥

墨西哥

越南

越南

日本

日本

韩国

韩国