For wet wipe manufacturers, a successful product relies more than just on the non-woven fabric or packaging design; the stability of the wet wipe liquid is a key factor truly impacting product quality and customer satisfaction.

If the wet wipe liquid is unstable, it may exhibit the following:

Yellowing and discoloration

Odor

Separation and precipitation

Microbial growth and mold

Entire batch returns and customer complaints

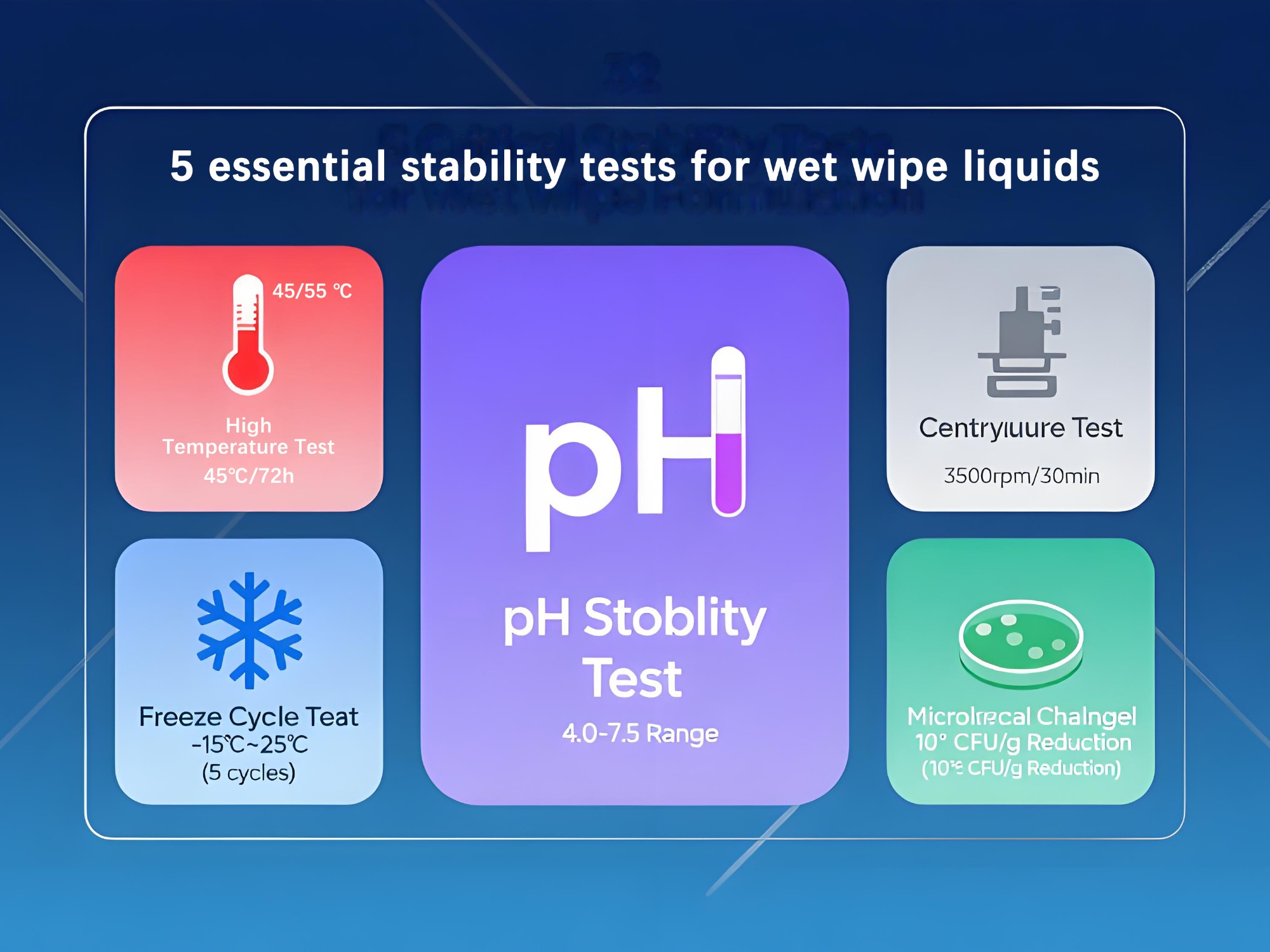

To ensure that potential issues with wet wipe liquids are detected and eliminated before use, ensuring the safety of finished wet wipes, five stability tests are essential quality control steps for every wet wipes factory.

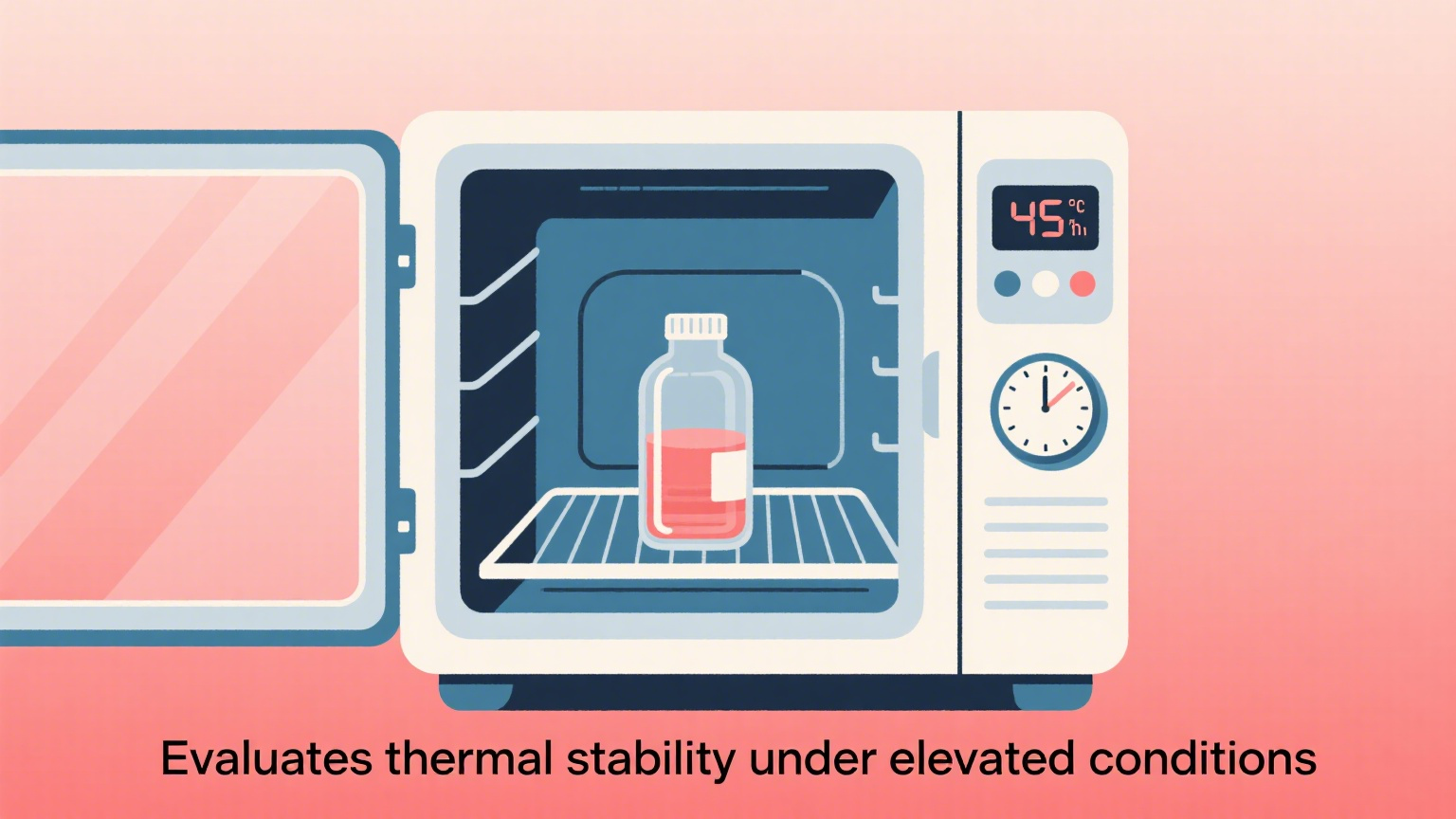

1 High-Temperature Test

Purpose:

Verify the high-temperature resistance of wet wipe liquids and determine whether they deteriorate during high-temperature transportation or storage in summer.

Method:

Place wet wipe liquid samples in incubators at 45°C and 55°C for 7 and 14 days, respectively, and observe:

Discoloration

Presence of precipitation or turbidity

Odor

Reminder:

Formulas containing fragrances, natural plant extracts, vitamins, etc. may be more susceptible to deterioration at high temperatures and should be tested specifically.

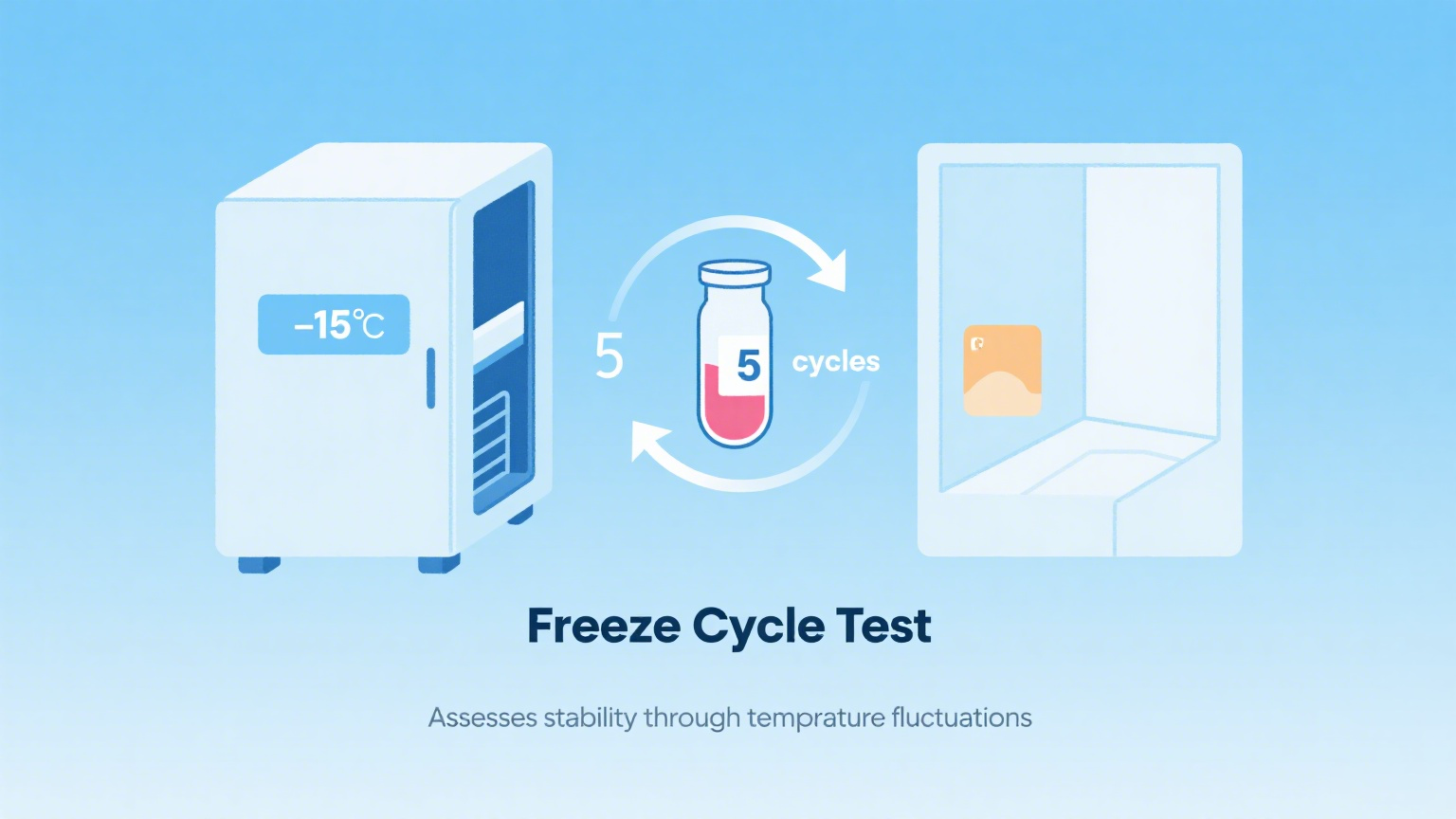

2 Freeze Cycle Test

Purpose:

Simulate low-temperature conditions encountered during winter storage, transportation, and export to cold countries to verify the stability of the wet wipe liquid and determine whether it delaminates or freezes, rendering it unusable. Method:

Place the sample in a freezer at -5°C for more than 24 hours, then return it to room temperature.

Repeat this process 3-5 times.

Observe for:

Liquid separation, precipitation, turbidity, sedimentation, or changes in viscosity.

Recommendation:

This test is recommended for products exported to cold northern regions, such as Europe, the United States, and Russia.

3 pH Stability Test

Purpose:

Develop an appropriate pH for the wet wipe liquid based on its different functions, and ensure that the pH remains stable under various conditions. Only a stable pH ensures the mildness and antiseptic properties of the wet wipe.

Method:

Use a pH meter to test the liquid's pH at room temperature, high temperature, and freezing conditions to ensure it remains within the appropriate range.

✅ Reference Range:

Baby wipes: pH 4.5–6.0

General cleaning wipes: pH 5.0–7.5

Why it matters:

pH fluctuations can weaken preservatives and increase the risk of microbial contamination in the wipes liquid.

4 Centrifuge Test

Purpose:

To simulate vibration or movement during shipping and test for emulsion or phase stability in the wipes liquid.

Method:

Spin the sample in a centrifuge at 3000 rpm for 30 minutes. Observe for:

Layer separation

Suspended particles

Emulsion breakdown

✅ Especially important for:

Wipes liquid formulas containing oils, emulsifiers, or essential oils.

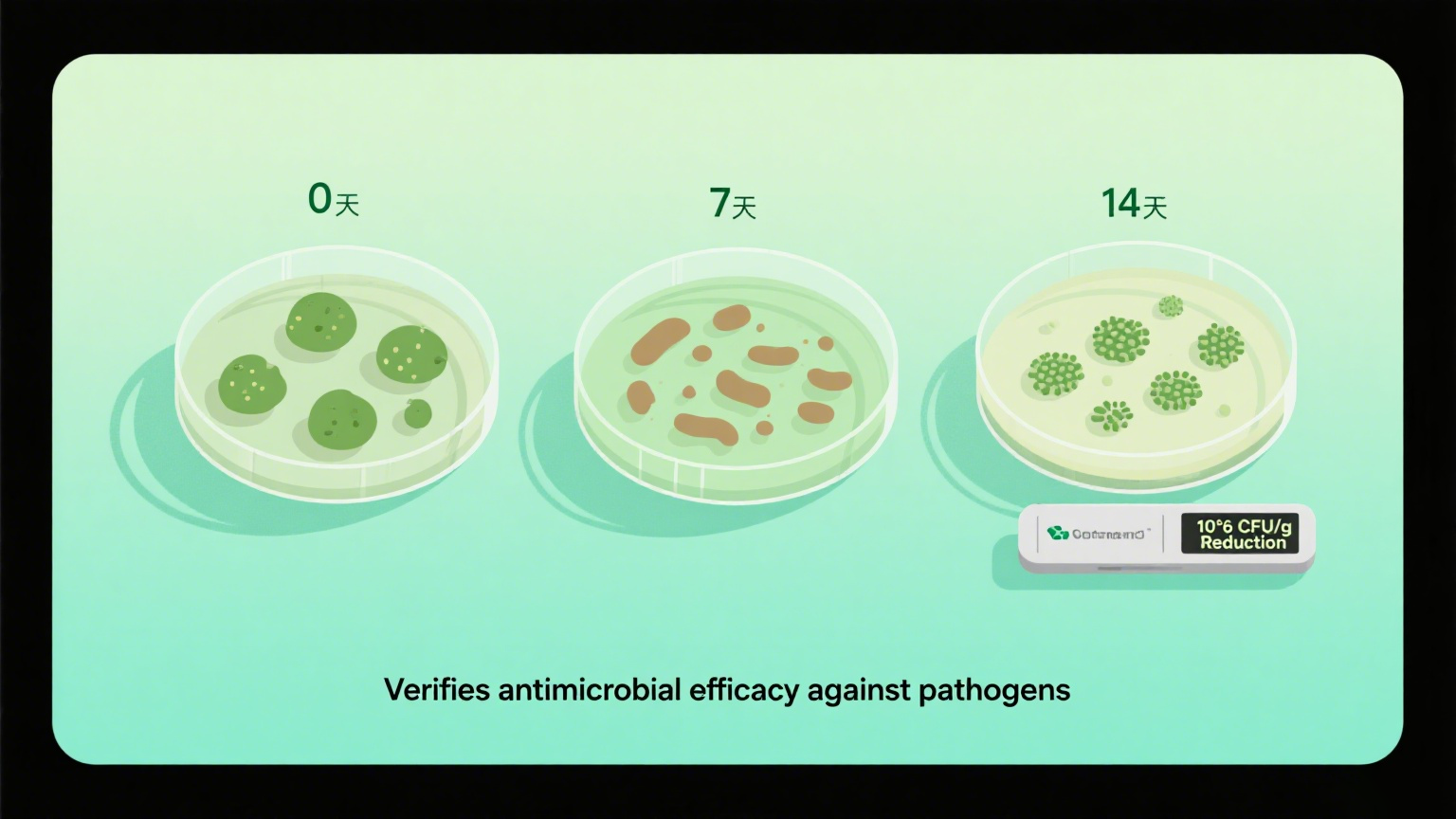

5 Microbial Challenge Test (Preservative Efficacy Test)

Purpose:

To test the effectiveness of the wipes liquid's preservative system in preventing microbial contamination.

Method (performed in lab):

Inoculate the formula with common microbes (e.g., Staphylococcus aureus, E. coli)

Monitor microbial count over time (typically 7, 14, 28 days)

Critical for:

Baby wipes liquid

Medical or sanitizing wipes liquid

Alcohol-free or natural wipes liquid formulas

✅ Summary: Stability Testing = Quality Assurance

Test Purpose Recommended For

High Temp Prevent spoilage in hot conditions Summer or overseas shipping

Freeze– Thaw Prevent separation in cold Export, winter, or cold climates

pH Stability Ensure safety and preservative integrity All wipes liquid types

Centrifuge Check emulsion stability Oil-based or fragranced wipes

Microbial Challenge Validate preservative system Baby, medical, alcohol-free

Conducting these tests before filling not only helps reduce customer complaints and product returns, but also ensures long-term customer trust and brand reputation.

English

English

USA

USA

西班牙语

西班牙语

俄罗斯

俄罗斯

葡萄牙

葡萄牙

印尼

印尼

巴基斯坦

巴基斯坦

尼日利亚

尼日利亚

孟加拉

孟加拉

墨西哥

墨西哥

越南

越南

日本

日本

韩国

韩国