During the production process, wet wipes are prone to microbial contamination due to various reasons, so it is necessary to add preservatives to prevent the growth of microorganisms.

Microbial contamination of wet wipes

(I) Sources of microbial contamination of wet wipes

Since wet wipes are rich in various active ingredients, they provide a good environment for the growth of microorganisms, and microbial invasion is inevitable during the production and use of wet wipes.

1. Production process contamination (from raw materials to products)

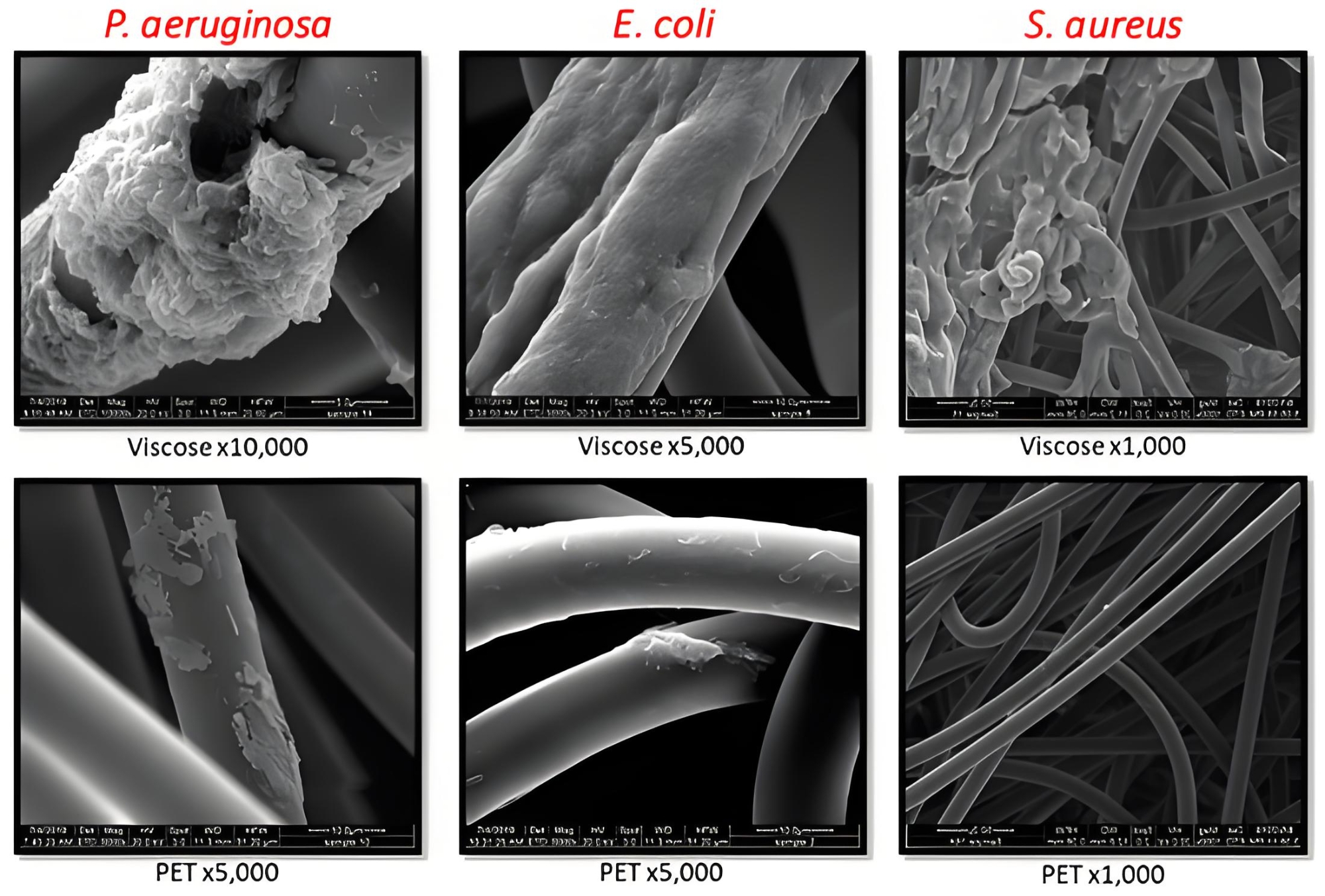

Also known as primary pollution, raw material contamination of wet wipes is the biggest cause of primary pollution. The raw materials that are extremely susceptible to microbial contamination are natural plant ingredients and their extracts, such as extracts from aloe vera, chamomile, Centella asiatica, ginseng, etc. These raw materials are derived from nature and are rich in nutrients, and are extremely susceptible to external microbial contamination. Other raw materials that are likely to be contaminated by microorganisms include: non-woven fabrics, surfactants, etc. Among them, special attention should be paid to water. Ion exchange water is mainly used in the production of wet wipes. Since active chlorine is removed, it is easy to be contaminated by bacteria.

2. Equipment and production tools pollution

For example, storage tanks, mixers, conveyor belts, packaging equipment, etc. may accumulate microorganisms.

3. Pollution in the production environment

Microorganisms in the air are mainly caused by dust flying from the ground; in addition, people's production and daily activities can cause a large number of microorganisms to enter the air.

(1) Factory air: There are a considerable number of dry-resistant bacteria, yeasts and mold spores in the factory air. Bacillus, Clostridium, Staphylococcus, Streptococcus, Corynebacterium and other bacterial species can be isolated from the air; Penicillium, Aspergillus, Cladosporium, Pulla, Mucor and yeast can also be isolated.

(2) Production personnel: The human body carries countless microorganisms in its normal state, and these microorganisms can be brought into the preparation from the production personnel.

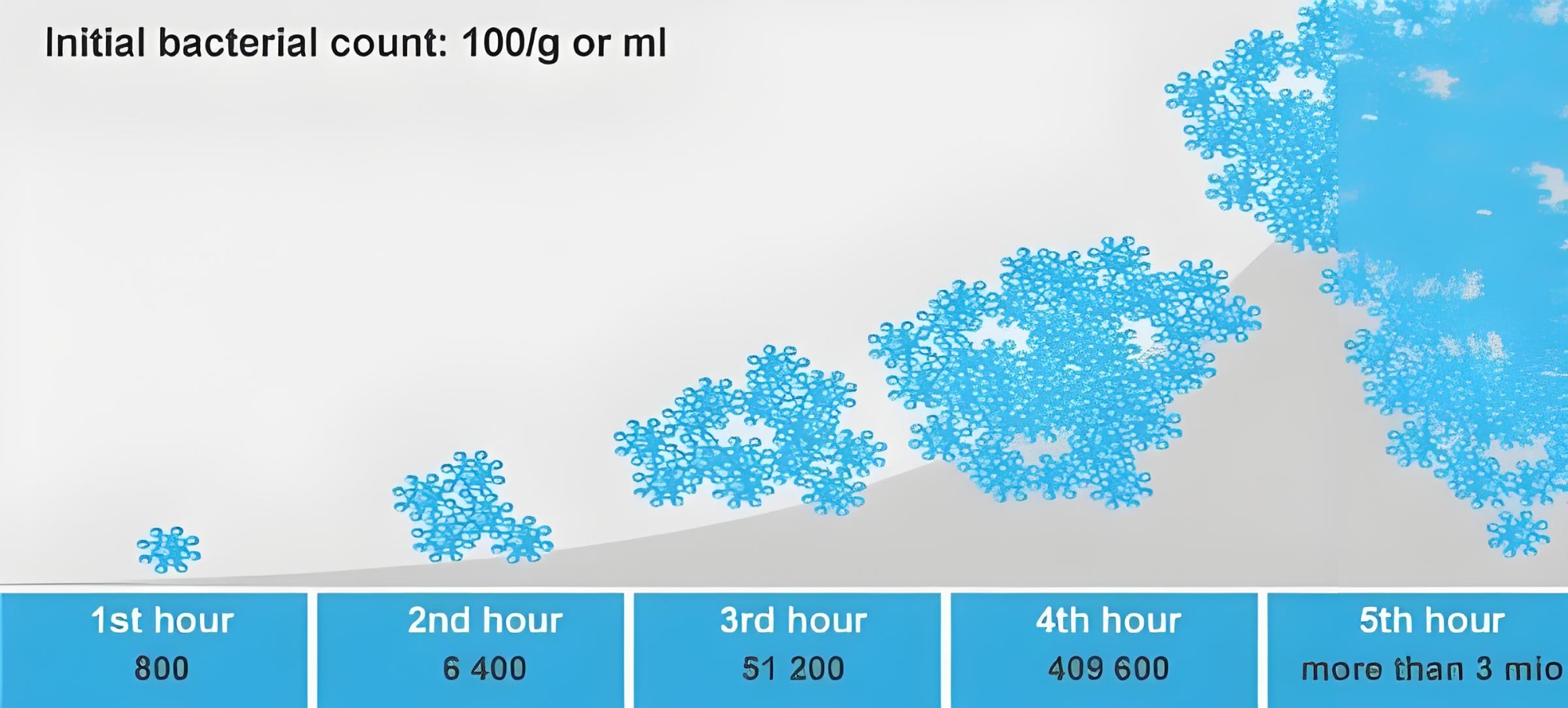

(II) Growth and reproduction of microorganisms in wet wipes

1. Relationship between the nutritional components of wet wipes and microorganisms

Wet wipes have a variety of raw materials, which provide the necessary carbon source, nitrogen source and minerals for the growth and reproduction of microorganisms.

2. The relationship between moisture in wet wipes and microorganisms

Moisture is a determining factor that determines whether microorganisms can grow and affects their growth rate. Water is also an important raw material for wet wipes production and an excellent solvent. Many wet wipes contain a considerable proportion of moisture, which is conducive to the growth of microorganisms.

3. The relationship between the pH, humidity, etc. of wet wipes and microorganisms

Bacteria grow appropriately under neutral and slightly alkaline conditions (pH6-8), molds grow appropriately under neutral and slightly acidic conditions (pH4-6), and the pH of wet wipes is about 4-7, which is suitable for the growth of microorganisms.

The optimum temperature for the growth of mesophilic bacteria is 20℃-40℃, and 37℃ is the optimum growth temperature for most pathogens. The optimum growth temperature for most molds and yeasts is 20℃-30℃, which is basically the same as the temperature for the production, storage and use of wet wipes.

The above factors all create conditions for microorganisms to survive and reproduce in wet wipes.

(III) Characteristics of wet wipes contamination

1. Wet wipes contain a certain amount of water, carbon and nitrogen sources for microbial growth and reproduction, and most of them are neutral, slightly alkaline or slightly acidic, which provide good conditions for the growth and reproduction of microorganisms. According to the survey, this type of wet wipes has the highest microbial contamination rate and the most contaminated microbial species. The detection rates are relatively high for fecal coliforms, Pseudomonas aeruginosa, and Staphylococcus aureus. In addition, Bacillus cereus, Klebsiella aeruginosa, Salmonella, Enterobacter, etc. were also detected.

2. Wet wipes are not only rich in water, but also have nutrients required for microbial growth, such as hydrolyzed protein, polyols, vitamins, etc.

3. Microbial contamination of wet wipes has the greatest impact on human health, especially eye wipes and makeup remover wipes used around the eyes. Once contaminated by pathogens, it will cause serious consequences.

(IV) Manifestations of microbial contamination of wet wipes

The raw materials and additives in wet wipes contain a large amount of nutrients and water, including carbon sources, nitrogen and water necessary for the growth and reproduction of microorganisms. Under suitable temperature and humidity, microorganisms will grow and reproduce in wet wipes, absorbing, decomposing and destroying the effective ingredients in wet wipes. They will deteriorate, mold and rot. The deterioration of wet wipes can be easily detected from the obvious changes in their color, odor and texture.

(1) Changes in color. Colored and colorless microorganisms grow and secrete pigments in their metabolites into wet wipes. For example, the most common T-4 bacteria causes wet wipes to produce yellow, black or gray fog spots and even stink.

(2) Changes in odor. Volatile substances produced by microorganisms, such as amines and sulfides, emit odors, and even microorganisms can decompose organic acids in wet wipes to produce acid gases, which makes wet wipes contaminated by microorganisms emit a sour odor.

(3) Enzymes in microorganisms (such as desmolysis enzymes) can hydrolyze lipids and proteins in wet wipes, break emulsions, and cause stratification, thinning, and water seepage. Liquid wet wipes will experience turbidity and other structural changes.

The deterioration of wet wipes will not only cause changes in color, fragrance, and taste. The quality will decline, and the decomposition products will irritate the skin during deterioration, and the propagated pathogens will cause human diseases.

Wet wipes are not only suitable for the treatment of acne, but also for the treatment of acne.

Establishment of wet wipes antiseptic system

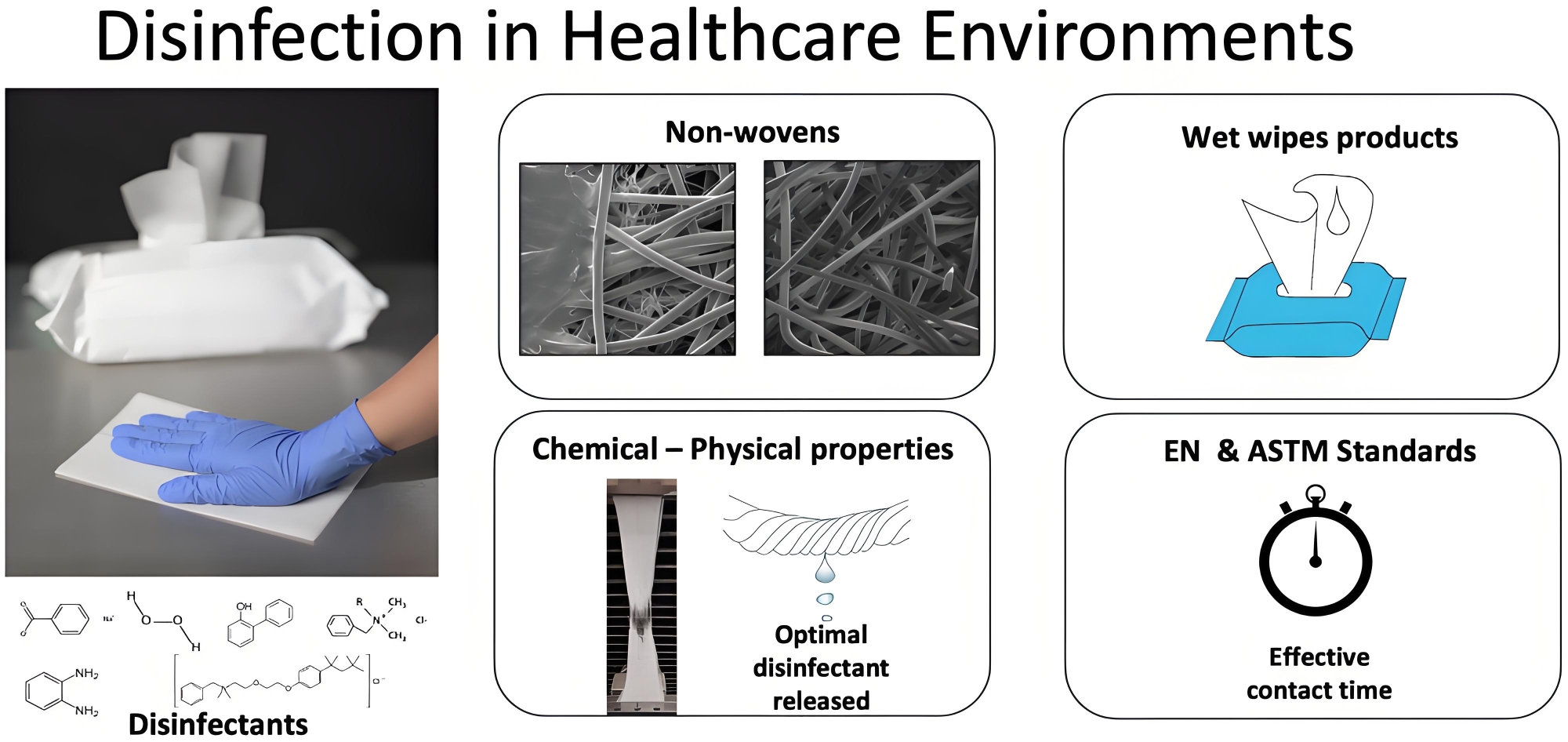

In order to eliminate secondary microbial contamination of wet wipes, wet wipes liquid (preservative/fungicide) is added to the wet wipes to kill and inhibit microorganisms and their reproduction, which plays a role in preventing the wet wipes from spoiling and deteriorating.

1. Definition of wet wipes liquid (preservative/fungicide)

In short, wet wipes liquid (preservative/fungicide) refers to substances that can prevent the growth of microorganisms. In wet wipes, the role of wet wipes liquid (preservative/fungicide) is to protect the product from microbial contamination and extend the shelf life of the product; ensure the safety of the product and prevent consumers from possible infection caused by using products contaminated by microorganisms. Wet wipes are contaminated by microorganisms and caused Deterioration, in general, can be reflected in the appearance. For example, mold and yeast often appear on the edge of the product packaging; products contaminated by microorganisms appear turbid, precipitate, change color, change pH value, foam, change taste, and if it is an emulsion, it may break and form lumps. If the amount of wet wipes liquid added is not enough, the microorganisms may adapt to the surrounding growth environment and develop drug resistance, resulting in the failure of preservation.

2. Mechanism of action of wet wipes liquid (preservative/fungicide)

The survival and reproduction of microorganisms in wet wipes depend on some environmental factors: physical aspects include temperature, environmental pH value, osmotic pressure, radiation, static pressure; chemical ... There are water sources, nutrients (C, N, P, S sources), oxygen, and organic growth factors.

Based on this, the mechanism of action of preservatives can be simply summarized as follows:

1) For most bacteria, the most suitable pH range for growth is close to neutral (6.5~7.5). Strong acids and strong bases are not suitable for the growth of microorganisms. For example, the common fruit acid products usually have a better preservative effect than neutral products;

2) Increasing or decreasing osmotic pressure can lead to rupture of cell membranes, and can also cause membrane shrinkage and dehydration;

3) In addition, surface tension is also one of the reasons that affect microbial growth. In some formulations with high surfactant dosages, microorganisms are not easy to grow. In this regard, cationic surfactants perform more prominently, while anions and non-ions have little physiological toxicity to microorganisms.

4) Under normal circumstances, the most suitable temperature for bacteria production is 30℃~37℃, while molds and yeasts are 20℃~25℃, so high-temperature disinfection can be used, but individual spores form a protective film after adapting to the environment, and they cannot be killed even at a high temperature of 80℃~90℃ in a short time.

The effect of wet wipes liquid (preservative/fungicide) on microorganisms can only take effect when it is in direct contact with microorganisms at a sufficient concentration. The wet wipes liquid first contacts the cell outer membrane, adsorbs, passes through the cell membrane into the cytoplasm, and then can exert its efficacy in various parts, hindering cell reproduction or killing it. In fact, it is mainly the effect of preservatives on cell walls and cell membranes, and also on the activity of enzymes that affect cell metabolism or on the genetic particle structure of some cytoplasmic parts.

3. Prevent process contamination

According to the source of microbial contamination, we can relatively prevent contamination from all aspects:

1) Prevent contamination of raw materials

There are many types of wet wipes non-woven fabrics and wet toilet papers, most of which are not sterilized and have conditions for the growth and reproduction of microorganisms. Many Gram-negative bacteria can grow well in the medium, and Gram bacteria, especially monosaccharides, often appear in most wet wipes media. In addition, a large amount of water is used in the production of wet wipes, which may also bring microorganisms into the finished product. Generally speaking, the quality of non-woven fabrics and wet toilet papers largely determines the quality of the finished product. Therefore, in the production process of wet wipes, it is necessary to establish a raw material testing procedure, formulate raw material microbial indicators, and adopt strict sterilization and disinfection methods. Raw materials are easily contaminated during storage, and moisture-proof containers should be used at the specified temperature and service life.

For raw materials contaminated by microorganisms, heat sterilization, ultraviolet sterilization, filtration sterilization, sedimentation sterilization and other methods are generally used. Thermal sterilization methods are very effective in killing general microorganisms.

Wet wipes generally use deionized water or distilled water, which will produce various bacteria after being stored for a few days. In order to ensure the quality of water, microorganisms in the water should be tested daily. If no obvious problems occur, the frequency of testing can be reduced, but this must be based on a proven effective system. However, for the microbial control device and each water point in the water treatment system, microbial testing should be carried out at least once a week. If the test result of a certain water intake point exceeds the standard, a comprehensive analysis must be carried out until the cause is found and decisive measures are taken to correct it.

2) Prevent environmental and equipment contamination

The design of the air system in the production environment is different for the specific requirements of each area of the factory. It should consider the quality of air required for operation in this area, which will require several different air handling systems, which are designed based on the air quality required for each service area. The design of these systems must consider several aspects, including the quality of incoming air, temperature, humidity, exchange rate and air purity requirements of the system design, and consider the location of inlet/outlet vents and the layout of ducts that control airflow patterns.

In humid areas, walls, ceilings, floors, pots, stirring paddles, feed pipes and utensils need to be regularly cleaned and sterilized because these places are conducive to the growth and reproduction of microorganisms. Commonly used disinfectants include sodium hypochlorite, formaldehyde, Sanisol, chlorhexidine acetate and ethanol.

3) Prevent packaging contamination

Unhygienic packaging materials (barrels, bottles, caps) can cause microbial contamination of wet wipes and need to be cleaned before use. Specific packaging is one of the measures to maintain the quality of wet wipes. The preservation of the same type of product has different effects on preventing microbial contamination depending on its packaging type. The effect of pump packaging for lotion wipes is better; the effect of using a screw cap for shampoo is better than that of a sliding cap.

4) Preventing operator contamination

Human skin, nose, ears, mouth, etc. all have microorganisms. If a towel is wet for a period of time, it will contain a large number of microorganisms (including Gram-positive bacteria). Therefore, good personal hygiene is an effective way to control microbial contamination. Employees who do not perform good personal hygiene will make all the above-mentioned work ineffective. Despite the best supplies, equipment, procedures and good cleaning and sanitation operations, contamination may still occur. Special sanitary clothing, sanitary hats, and sanitary shoes for cleaning should be worn, and the hands of production personnel should be disinfected. Generally, it is washed with soap and water first and then immersed in chlorine-containing disinfectant or 75% ethanol, or disinfected with new chlorhexidine and chlorhexidine acetate.

English

English

USA

USA

西班牙语

西班牙语

俄罗斯

俄罗斯

葡萄牙

葡萄牙

印尼

印尼

巴基斯坦

巴基斯坦

尼日利亚

尼日利亚

孟加拉

孟加拉

墨西哥

墨西哥

越南

越南

日本

日本

韩国

韩国