In the production of wet wipes, producing high-quality products requires not only high standards for non-woven fabrics and packaging materials, but also, crucially, the use of the wet wipe liquid. Many factories encounter problems such as liquid separation, foaming, unstable formulas, or shortened shelf life during wet wipe production. These issues are often related to improper liquid addition order, mixing process, and ratio control. This article will detail the key aspects to consider in wet wipe production and introduce the correct usage of our wet wipe liquid formula, helping factories easily improve production efficiency and product stability.

I. Key Considerations in Wet Wipe Production

1. Water and Raw Material Quality

The main component of wet wipe liquid is water, therefore, water quality directly affects the quality of the finished product. It is recommended to use pure water (RO water or deionized water), and avoid using tap water to prevent contamination from impurities, ions, or bacteria, which can lead to abnormal formula reactions or product mold growth.

2. Cleaning and Disinfection of the Mixing System

The mixing tank, delivery pipelines, storage tanks, and other equipment must be thoroughly cleaned before use and disinfected with alcohol or other safe disinfectants. Residual liquid or impurities from the previous batch can easily affect the stability and appearance of the new batch of wet wipes.

3. Stirring Speed and Time Control

Stirring too quickly can create bubbles, leading to foaming or unstable filling; insufficient stirring may result in uneven component distribution. It is generally recommended to mix at a low speed for 5–10 minutes, until the liquid is completely mixed and appears transparent.

4. Temperature and Storage Conditions

Liquid preparation is best carried out at room temperature (20–30℃). Temperatures that are too high or too low may cause some functional components in the liquid to become ineffective. The finished liquid should be stored in a sealed container, avoiding direct sunlight and high temperatures to ensure the stability and longevity of the wet wipes.

II. How to Correctly Add Our Wet Wipe Liquid Formula

Our wet wipe liquid is a ready-to-use concentrated formula, specifically designed for wet wipe manufacturing plants. It is easy to use, highly stable, and saves labor and time costs.

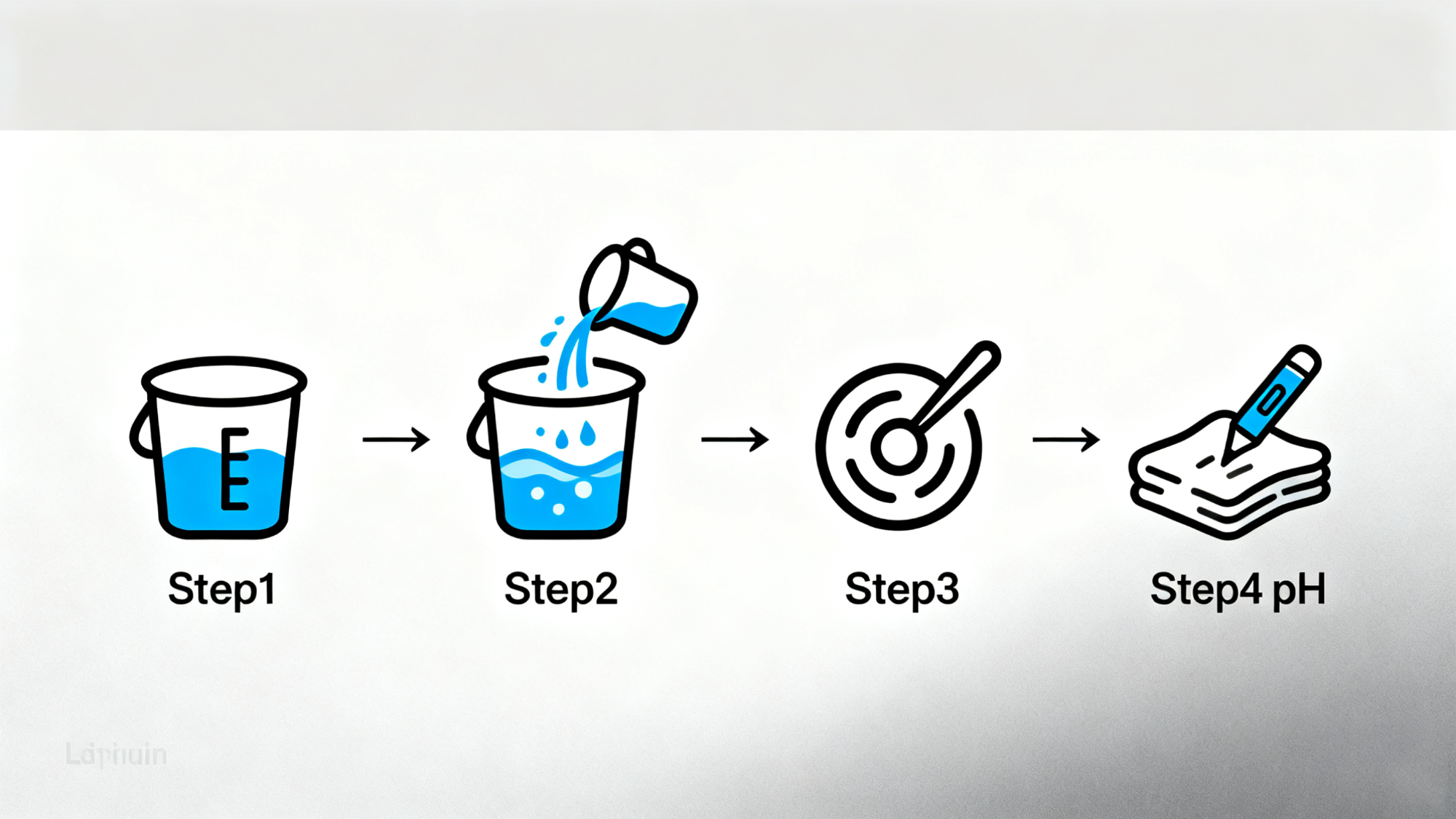

Here are the recommended steps for use:

Step 1: Prepare Pure Water

Add the prescribed amount of pure water to the mixing tank of the wet wipe machine (e.g., the volume depends on the size of the mixing tank, generally 100L, 500L, or 1000L, etc.).

Step 2: Add Our Wet Wipe Liquid According to the Proportion

Dilute the wet wipe liquid into the water according to the actual needs. For example:

Recommended Proportion: Add according to the formula ratio

The proportion can be adjusted according to different types of wet wipes (baby wipes, disinfecting wipes, makeup remover wipes, etc.).

Simply pour the wet wipe liquid directly into the mixing tank and stir with the pure water.

Stir until well mixed; no additional heating or complicated equipment is required, making it very simple and convenient.

Step 3: Stir and Homogenize

Stir in the mixing tank for 5–10 minutes to fully mix the liquid until it is uniform and transparent.

Our formula has good water solubility and dissolves completely in water, requiring no additional emulsification step.

Step 4: Testing and Use

After mixing, wet wipes can be directly impregnated and filled. It is recommended to test the pH value (generally 5.0–6.5) before production to ensure compliance with product standards.

III. Why Choose Our Wet Wipe Liquid Formula

Our wet wipe liquid is designed specifically for B2B factory clients, helping you easily improve production efficiency:

Ready-to-use concentrated liquid – No complex formula development required, simply dilute and use.

High stability and safe preservative system – Ensures the wipes do not discolor or mold throughout their shelf life.

Compatible with various fabrics and fragrances – Suitable for different materials such as non-woven fabrics, bamboo fiber cloth, and wet toilet paper; fragrances can be freely combined.

Saves time and labor costs – The factory only needs one bucket of water + one bucket of liquid; simply mix to begin production.

Customizable formulas – We can customize preservative-free, alcohol-free, and natural formulas according to the client's national regulations and target market needs (such as EU/US standards).

IV. Frequently Asked Questions (FAQ)

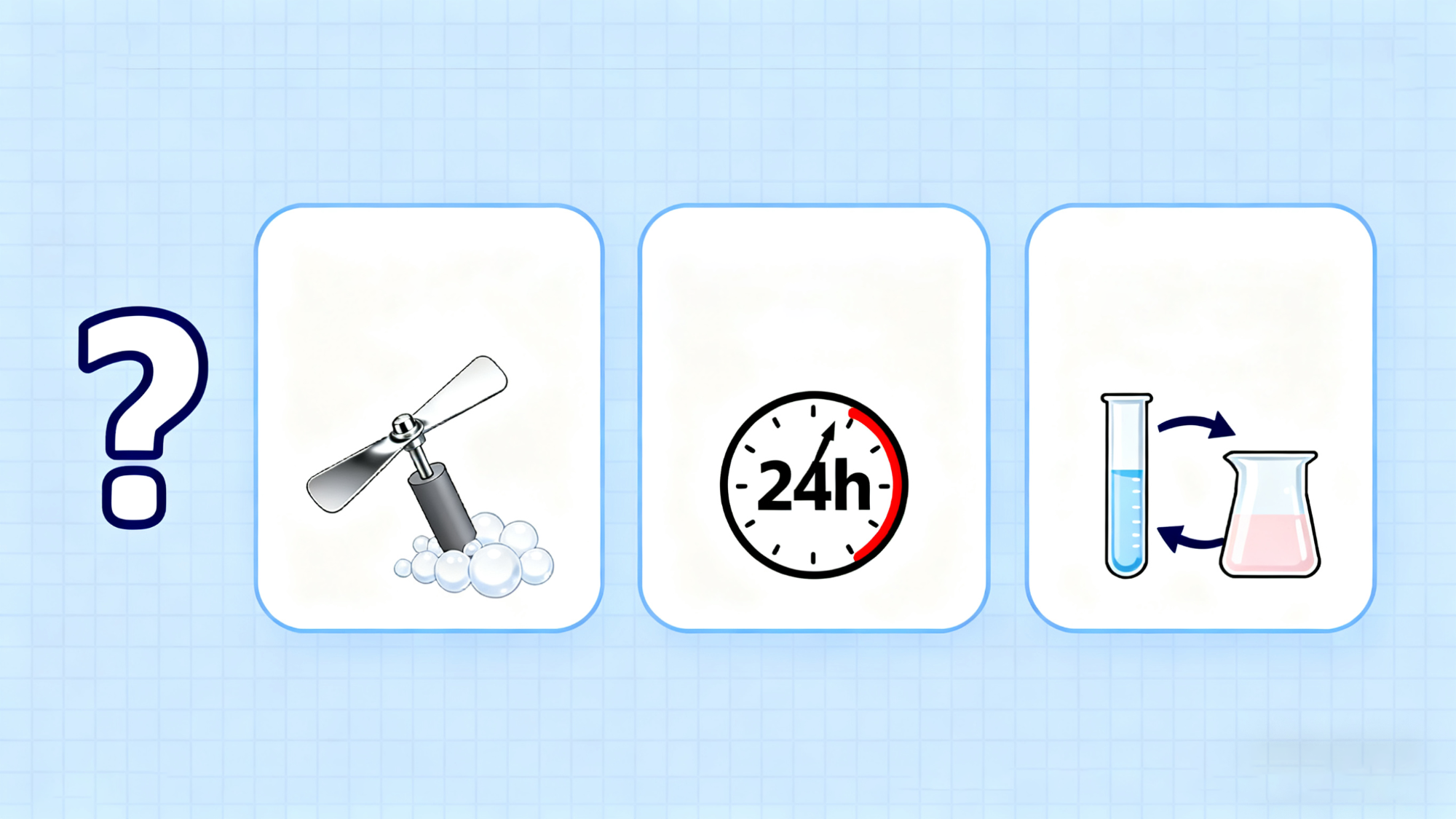

Q1: What should I do if foam appears during mixing?

→ We recommend reducing the mixing speed or using an anti-foaming mixing paddle. Our liquid contains an anti-foaming system and generally will not foam.

Q2: How long after dilution should the liquid be used?

→ It is recommended to use it within 24 hours to avoid prolonged exposure and potential microbial contamination.

Q3: Can it be mixed with the customer's own additives?

→ Yes, but compatibility testing is required beforehand to ensure system stability and transparency.

V. Summary While wet wipe production may seem simple, the method of adding the liquid formula, the proportion control, and the mixing process directly affect product quality.

Our wet wipe liquid formula helps factories simplify production processes, reduce costs, and improve product consistency, making production more efficient, safe, and controllable.

If you are a wet wipe manufacturer, please contact us for detailed formula instructions and sample testing.

We will assist you in creating more stable and competitive wet wipe products.

English

English

USA

USA

西班牙语

西班牙语

俄罗斯

俄罗斯

葡萄牙

葡萄牙

印尼

印尼

巴基斯坦

巴基斯坦

尼日利亚

尼日利亚

孟加拉

孟加拉

墨西哥

墨西哥

越南

越南

日本

日本

韩国

韩国